The rice mill in question at Bhadrak is considered to have one of the best modern plants with updated technological advancements. The production capacity of the plant is 4 tons per hour. The plant has all sorts of equipment to produce quality rice. The unit has most updated warehouses in order to cope up with the storage for finished and unfinished goods.

The par boiling plant has a capacity of 20 tons / batch consisting 8 tanks of 2.5 tons capacity each. The tanks are made of mild steels (MS). The total package involves parboiling tanks, SS strainers, paddy receiving bin, supporting structure bucket elevator, belt conveyor pumps and pipeline and fittings. Generally, this type of plant requires two sets of parboiling plants, i.e. 16 tanks. But in the project latest technology is used where only one set of tanks (8 Nos.) is used along with semi automation through PLC (Programmed Logic Control) system where by parboiling period / time is cut down to half resulting in four batches per day from a single set of plants instead of two batches. This technology is already a proven technology largely used nowadays.

There are two driers 20 tons capacity each made of stainless steels (SS), SS Driers are preferred over MS driers all over cases due to their long life and quality of output. The driers have 90-degree baffles built into it. The total machinery set up of the drying plant includes centrifugal blowers, steam heat exchangers, bucket elevators, pipeline and fittings.

The boiler as proposed were installed as multi tubular 3 pass wet back over teed smoke tube package boiler. It has a steam generating capacity of 4000 kgs / hour (F & A 100-degree Celsius). The boiler has an operating pressure of 10.54 kg / cm (2) / 150psl. It is a fully automatic packaged boiler capable of living and uninterrupted. The boiler finalized for the project belongs to “Thermax Limited” which is the one of the best manufacturing producers in India.

In a boiled plant a paddy pre cleaner is very important. It is the first step of cleaning the raw paddy collected. The paddy pre-cleared proposed for this project consist of a rotary grain separator, aspiration channel, dust cyclone, blower, air lock and gear motor. The pre-cleaner finalized for the project belongs to “John Fowler” the most famous brand in paddy pre-cleaning machineries in the world.

This is totally a supporting machine essential for any processing plant using agricultural commodities. It is a large-scale weighing assembly which can weigh up to 60 tons of commodity at a time (maximum). This machine works electronically to give accurate results. The weighbridge is used when any party comes to for delivery of raw materials to the factory. Generally, without it there is a possibility of weighing loss to the company and is pretty essential.

The milling machinery has been installed in this plant which has been sourced from M/S Milltec Machinery Private Limited Bangalore, the No. 1 manufacturers of prominent rice milling machineries in India in terms of turnover and volume. M/S Miltech Machinery Private Limited is having more than 15 years track record of having supplied a lot of successful rice mill projects throughout India. They also have the excellent services back up facility for the state of Odisha with five trained engineers in different locations in Odisha. They provide service to any of their units within 24 hours from the time of lodging of the complaint.

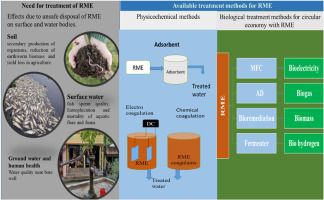

The mill does not generate any hazardous toxic effluents. The plant has an exhaustive disposal system whereby all wastages can be suitably dealt. rice mills generally generate two types of effluents: one is air pollutants and other one is water pollutants. The waste water coming out of the parboiling & drying process contains biological oxygen demand (BOD) and chemical oxygen demand (COD) at around 1500 ppm and 2500 ppm. The water treatment plant is aimed at reducing the same to less than 30 ppm to 250 ppm respectively. The water treatment plants include neutralization tank, effluent feed pumps, upflow anaerobic sludge blanket (USAB) reactor, moving bed bio reactor (MBBR). Sludge settling tank & sludge drying bed. The final product can be recycled as water can be reused for paddy / rice processing. There is also a little amount of biogas that is generated at the end of the system which can also be used as a fuel. For the air pollution control two devices are mainly planned, one is “Cyclomax” and the other is forced draught (FD) fans. These machines clean and remove all the air-based impurities and release the unharmful air through the chimney. The company has consent from the state pollution control board, Odisha.

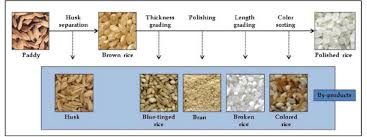

The basic objective of a rice milling system is to remove the husk and the bran layers, and produce an edible, white rice kernel that is sufficiently milled and free of impurities. Depending on the requirements of the customer, the rice should have a minimum number of broken kernels.